The following definitions are extracted from WDMA I.S.1A, Industry Standard for Architectural Wood Flush Doors and WDMA I.S.6A, Industry Standard for Architectural Stile and Rail Doors

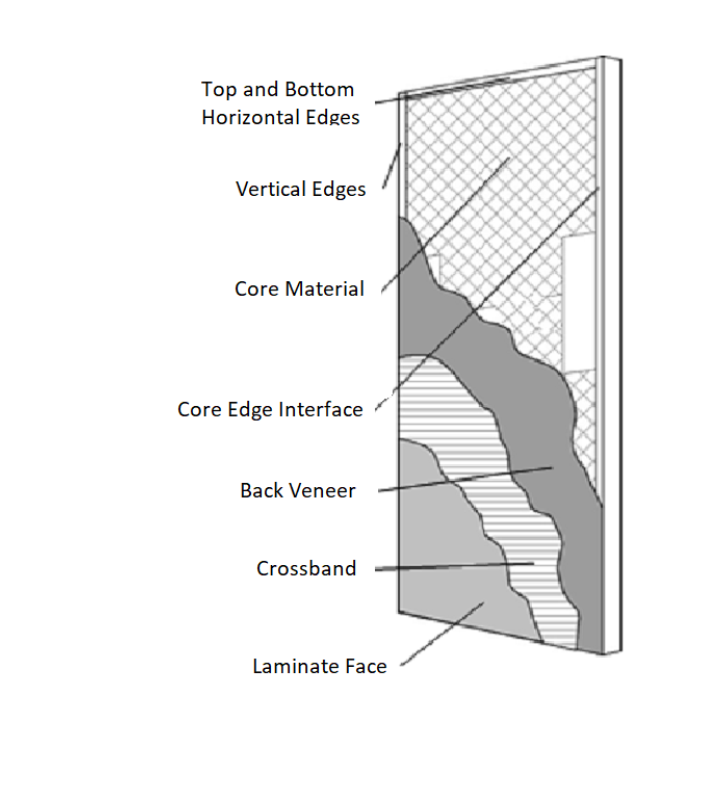

Anatomy of a Flush Door

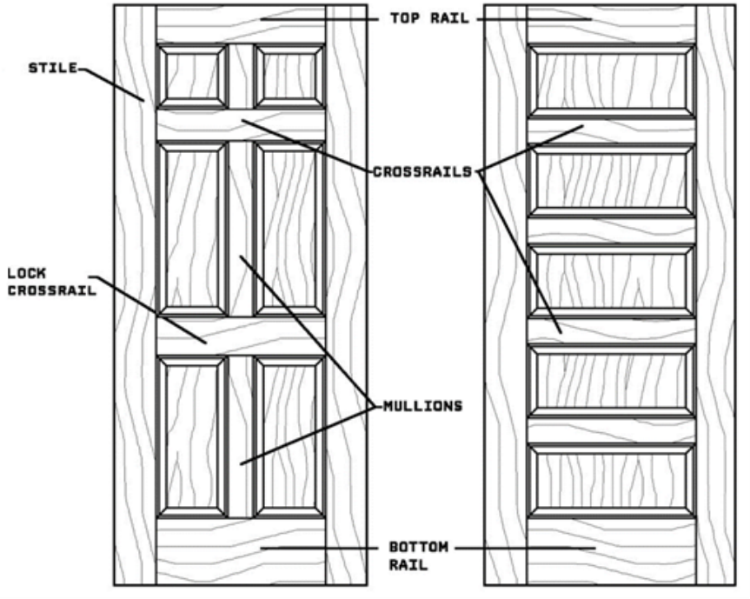

Anatomy of a Stile and Rail Door

Glossary

Astragal- A molding or trim attached to the meeting edge of one door of a pair of door(s) which prevents swing-through and covers the gap where the doors meet when closed.

Balance Match- Two or more veneer components or leaves of equal size to make up a single face.

Barber Pole- An optical effect that often occurs when veneers are book matched, resulting in an alternating dark and light appearance. This is caused by slicing veneer, creating tight and loose sides that are placed adjacent to one another in the book matching process. The tight and loose sides reflect light differently, resulting in the varying appearance.

Bark Pocket- Bark around which normal wood has grown.

Bevel- A machine angle other than a right angle, i.e., a 3 degree bevel that is equivalent to a 1/8 inch drop in a 2 inch span (1 mm in 16mm).

Bird Peck- A mark or wound in a tree or piece of wood caused by birds pecking on the growing tree in search of insects.

Blended Repair Tapering- A repair referring to end splits, repaired with wood or filler similar in color to blend well with adjacent wood.

Blending- Color change that is detectable at a distance of 6 ft. to 8 ft. (1.8 m to 2.4 m) but which does not detract from the overall appearance of the door.

Blocking- A material used to replace core material in specific locations to provide improved screw holding for the attachment of hardware or provide additional structural door reinforcement.

Bonded Core- Stiles and rails are securely glued to the core prior to application of crossbanding, door skins, veneers or laminate.

Book Match- Adjacent pieces of veneer from a flitch or log are opened like a book and spliced to make up the face with matching occurring at the spliced joints. The fibers of the wood, slanting in opposite directions in the adjacent sheets, create a characteristic light and dark effect when the surface is seen from an angle.

Bow- A curvature along the door height, or a deviation from a flat plane from end to end. A deviation, flatwise, from a straight line drawn from end to end or top to bottom of a piece as measured at the point of greatest distance from the straight line.

Burl- A figure created by abnormal growth or response to injury that forms an interwoven, contorted, or gnarly mass of dense woody tissue on the trunk or branch of the tree.

Burl, conspicuous- A swirl, twist or distortion in the grain of the wood which usually occurs near a knot or crotch. A conspicuous burl is associated with abrupt color variation and/or a cluster of small dark piths caused by a cluster of adventitious buds.

Butt Joint- A joint formed by square edge surfaces (ends, edges, and faces) coming together. Also referred to as a end butt joint, edge butt joint.

Cathedral Grain- A grain appearance characterized by a series of stacked and inverted "V"s, or cathedral type of springwood (earlywood) summerwood (latewood) patterns common in plain sliced (flat cut) veneer (see split heart).

Center Match- An even number of veneer components or leaves of equal size (prior to edge trimming) matched with a joint in the center of the panel to achieve horizontal symmetry.

Certified Wood- Wood products that have been qualified by an independent third party agency as satisfying their proprietary requirements for responsible environmental practices.

Checks- Small slits running parallel to grain wood, caused chiefly by strains produced in seasoning and drying.

Comb Grain- A rift cut veneer with exceptionally straight grain and closely-spaced growth increments resembling the appearance of long strands of combed hair

Compatible for color and grain- Components selected so that lighter-than-average color components are not adjacent to darker-than-average color components, no sharp contrasts in color exist between adjacent components, and grain of adjacent components does not vary widely and is similar in grain, character, and figure.

Compatible Species- Different species which are able to exist in a harmonious combination of color and grain.

Component (Of Face Veneer)- An individual piece of veneer that is joined to other pieces to achieve a full length and width face. Terms used interchangeably with component in the context of the face are piece and leaf.

Composite- A composite whose ingredients include cellulosic elements. These cellulosic elements can appear in the form of, but are not limited to: distinct fibers, fiber bundles, particles, wafers, flakes, strands and veneers. These elements may be bonded together with naturally occurring or synthetic polymers. Also, additives such as wax or preservatives may be added to enhance performance.

Composite Panel- A panel composed of a wood derivative such as MDF. Used for opaque finishes.

Conspicuous- See burl, conspicuous and knots, conspicuous pin.

Core- The innermost layer or section in component construction. For typical constructions see: Particleboard Core, Medium Density Fiberboard Core, Structural Composite Lumber Core, Staved Lumber Core, Laminated Veneer Lumber Core, Fire Resistant Composite Core and other special core types.

Core, Fire Resistant- A door core material meeting fire listing requirements for fire protection of 20 minutes or greater.

Cross Bar (Veneer)- Irregularity of grain resembling a dip in the grain running at right angles, or nearly so, to the length of the veneer.

Cross Grain (Cross Figures)- Grain direction irregularity due to interlocked fibers, uneven annual rings, or to the intersection of a branch and stem forcing the visual line of the grain to run at an angle to the length of the wood. It is characterized by mild or dominant patterns across the grain in some faces. Also known as Cross Figures

Crossbanding- A ply placed between the core and face veneer in 5-ply construction or a ply placed between the back and face of a 3-ply skin in 7-ply construction, typically of hardwood veneer or engineered wood product.

Cup- A deviation in the face of a piece from a straight line drawn from end to end of a piece as measured at the point of greatest distance from the straight line.

Defect, Open- Checks, splits, open joints, knotholes, cracks, loose knots, wormholes, gaps, voids, or other opening interrupting the smooth continuity of the wood surface.

Discolorations- Stains in wood substances. Some common veneer stains are sap stains, blue stains, stain produced by chemical action caused by the iron in the cutting knife coming into contact with the tannic acid in the wood, and those resulting from the chemical action of the glue.

Door Frame- A group of components (wood, composite, aluminum or steel) that are assembled to form an enclosure and support for a door. Also known as door jambs.

Door, Louver- A door assembly of stiles and rails where the interior is filled with slat or chevron louvers.

Doze- A form of incipient decay characterized by a dull and lifeless appearance of the wood, accompanied by a loss of strength and softening of the wood substance.

Edge Band- A strip along the outside edges of the two sides and/or top and bottom of the door (See stiles/vertical edges, rails/horizontal edges).

Edge Glued (Edge Joint)- When the edges of boards are glued together to increase the width.

End Match- Butting adjacent veneer leaves on one panel end to end in sequence. Veneer leaves are book matched end to end. Generally used for very long panels or for projects in which only short-length veneers are available.

Face Veneer- The outermost exposed wood veneer surface of a veneered wood door.

Few- A small number of characteristics (generally less than five) without regard to their arrangement in the panel.

Figure- The natural pattern produced in the wood surface by annual growth rings, rays, knots, and natural deviations. From the normal grain, such as interlock and wavy grain, and irregular coloration.

Finger Joint- A series of interlocking fingers precision cut on the ends of two pieces of wood which mesh together and are held rigidly in place with adhesive.

Fire Rated Doors- A door complying with NFPA 80 that is listed and labeled by a qualified testing agency for fire-protection ratings. Ratings are indicated, based on testing at positive pressure, according to NFPA 252 or UL 10C, or at neutral pressure according to UL 10B. Doors can be rated as resisting fire for 20 minutes, 30 minutes, 45 minutes, 60 minutes, or 90 minutes. The door must be tested and carry an identifying label from a qualified testing and inspection agency.

Fire Resistant Composite Core- A core, typically incorporating minerals rather than wood fiber as the primary component, designed to improve fire resistance and thermal transmission,

Flake- See Fleck, Ray.

Flat-Cut- See Plain-Sliced.

Fleck, Ray (Flake)- Portion of a ray as it appears on the quartered or rift cut surface. Fleck is often the dominant appearance in oak.

Flitch- A complete bundle of veneers sheets laid together in sequence as they are cut from a given log or section of a log.

Gaps- 1) An unfilled opening in a continuous surface or between adjoining surfaces. 2) An open slit in the inner ply or plies or improperly joined veneer when joined veneers are used for inner plies.

Grain- The direction, size, arrangement and appearance of the fibers in wood or veneer.

Grain Slope- Expression of the angle of the grain to the long edges of the veneer component.

Grain Sweep- Expression of the angle of the grain to the long edges of the veneer component over a 12 inch (300 mm) length from each end of the door.

Hairline- A thin, perceptible line showing at the joint of two pieces of wood.

Half-round Slicing- Veneer slicing method similar to rotary slicing, in which the piece being sliced is secured to a “stay log” device that permits the cutting of the log on a wider sweep than when mounted with its center secured in the lathe to produce rotary sliced veneer. Plain-sliced or flat-sliced veneer can be produced this way. A type of half-round cutting is used to achieve plain-sliced or flat-cut veneer

Hardboard- Homogeneous panels manufactured primarily from inter-felted lignocellulosic (wood) fibers consolidated under heat and pressure with density of 31 lb/ft3 (497 kg/m3) or more.

Hardwood- General term used to designate lumber or veneer produced from temperate zone deciduous or tropical broad- leaved trees in contrast to softwood, which is produced from trees which are usually needle bearing or coniferous. The term does not infer hardness in its physical sense.

Heartwood- The non-active center of a tree generally distinguishable from the outer portion (sapwood) by its darker color.

High Pressure Decorative Laminate (HPDL)- A high impact resistant surface material consisting of decorative surface paper impregnated with melamine resins pressed over multiple kraft paper layers saturated with phenolic resins, thermoset at high pressure and temperature.

High Density Fiberboard (HDF)- The generic name for a panel made out of exploded wood fibers that have been highly compressed and where the bonding of the wood fibers requires no additional materials, although resin is often added.

Holes, Worm- Holes resulting from infestation by worms greater than 1/16 inch (1.6 mm) in diameter and not exceeding 5/8 inch (16 mm) in length.

Intumescent- A material applied to the surface of flammable products to reduce flammability that expands when exposed to extreme heat or fire to fill any gap between the door and frame or between doors.

Joint- The common edge between two adjacent materials in the same plane.

Joint, Edge- Joint running parallel to the grain of the wood.

Joint, Open- Joint in which two adjacent pieces of veneer in the same plane do not fit tightly together.

Knife Cuts per inch (KCPI)- A measure of the smoothness of machined lumber. Can be determined by holding the surfaced board at an angle to a strong light source and counting the visible ridges per inch, usually perpendicular to the profile. The surface is smoother with more knife marks per inch.

Knife Marks- Very fine lines that appear across the panel veneer or wood solids that can look as though they are raised resulting from some defect in the lathe knife that cannot be removed with sanding.

Knot- Cross section of tree branch or limb with grain usually running at right angles to that of the piece of wood in which it occurs.

Knot Holes- Voids produced when knots drop from the wood in which they were originally embedded.

Knots, Blending Pin- Sound knots 6.4 mm (1/4 inch ) or less that generally do not contain dark centers. Blending pin knots are barely detectable at a distance of 1.8 m to 2.4 m. (6 ft. to 8 ft ), do not detract from the overall appearance of the panel, and are not prohibited from appearing in all grades.

Knots, Conspicuous Pin- Sound knots 6.4 mm (1/4 inch ) or less in diameter containing dark centers.

Knots, Open (Knot Holes)- Openings where a portion of the wood substance of the knot was dropped out, or where cross checks have occurred to produce an opening. (See Dead Knots)

Knots, Spike- Knots cut from 0o to 45o to the long axis of limbs.

Laminated Veneer Lumber Core (LVLC)- Manufactured by laminating veneer with all grain laid-up parallel. It can be manufactured by using various species of wood fiber in various thicknesses.

Lap (Veneer)- A condition where one piece of veneer in the same ply overlaps another piece.

Loose Side- In knife-cut veneer, that side of the sheet that was in contact with the knife as the veneer was being cut, and cutting checks (lathe checks) because of the bending of the wood at the knife edge.

Low Pressure Decorative Laminate (LPDL)- A decorative surface paper that is saturated with reactive resins. During hot press lamination, the resin flows into the surface of the substrate, creating a hard crosslinked thermosetting permanent bond and permanently changing the characteristics of both the paper and the board.

Louver- A panel constructed of slats installed in a door or openings to allowing various degrees of light, air, or sound passage. May be constructed as adjustable. Common types are slat and Chevron – an inverted "V” wood louver (vented or non-vented).

Medium Density Fiberboard (MDF)- A generic term for a composite panel product or core manufactured from lignocellulosic fibers and a bonding system cured under heat and pressure in a hot press by a process in which the added binder creates the entire bond. MDF is generally denser than plywood and particleboard

Medium Density Overlay (MDO)- Typically MDO is kraft paper saturated with resin and cured under high heat and pressure to make a hard, smooth, paintable surface.

Medium Density Fiberboard Core (MDFC)- Wood fiber and/or agri-fiber based materials that comply with ANSI A208.2.

Meeting Edges- Two adjacent door edges not separated by a mullion or transom bar. These are found in pair, Dutch door and door & transom applications.

Mineral- See Streaks, Mineral.

Mineral Core- See Core, Fire Resistant.

Mineral Stain- Olive and greenish-black streaks believed to designate areas of abnormal concentration of mineral matter; common in hard maple, hickory, and basswood. Also called Mineral Streak.

Mineral Streaks- Sharply contrasting elongated discoloration of the wood substance.

Natural- When referring to color and matching, veneers containing any amount of sapwood and/or heartwood.

Neutral Pressure- A fire door test procedure where the neutral pressure plane is at or near the top of the door. Sometimes referred to as negative pressure.

Nominal- 1) A term that designates a stated dimension as being approximate and subject to allowances for variation. 2) The average sizes (width and thickness) of lumber just out of the sawmill before being processed into usable board stock. Always larger than finished dimensions.

Not Noticeable- Not readily visible without careful inspection (as a measurement of natural or machining characteristics).

Not Restricted- Allowed, unlimited.

Occasional- A small number of characteristics that arearranged somewhat diversely within the face.

Particleboard- A generic term for a composite panel primarily composed of cellulosic materials (usually wood), generally in the form of discrete pieces or particles, as distinguished from fibers, bonded together with a bonding system, and which may contain additives. Particleboard may be further defined by the method of pressing. When pressure is applied in the direction perpendicular to the faces as in a conventional multi platen hot press, they are defined as flat platen pressed. When the applied pressure is parallel to the faces, they are defined as extruded.

Particleboard Core- Wood fiber and/or agri-fiber based materials that comply with ANSI A208.1, minimum grade LD-1.

Pitch- An accumulation of resin that occurs in separations in the wood or in the wood cells themselves.

Pitch Pocket- A well-defined opening between the annual growth rings that contains pitch.

Pitch Streak- A well-defined accumulation of pitch in the wood cells in a more or less regular streak.

Pith- A small, soft core occurring in the center of the log.

Plain Slicing (Flat Cut)- Veneer sliced parallel to the pith of the log and approximately tangent to the growth rings to achieve flat cut veneer. Plain sliced veneer can be cut using either a horizontal or vertical slicing machine or by the half-round method using a rotary lathe.

Plank Matched- A face containing specially selected and assembled dissimilar (in color, grain and width) veneer strips of the same species, and sometimes grooved at the joints between strips, to simulate lumber planking.

Pleasing Match- A face containing components, which provide a pleasing overall appearance. The grain of the various components need not be matched at the joints. Sharp color contrasts at the joints of the components are not permitted.

Ply- A single sheet of veneer or several strips laid with adjoining edges that may or may not be glued, which forms one veneer lamina in a glued panel. In some constructions, a ply is used to refer to other wood components such as particleboard or MDF.

Positive Pressure- A fire door test procedure where the neutral pressure plane is located at 40 inches (1 m) above the sill.

Quartered (Quarter-sliced, Quarter Cut)- unlimited straight grain appearance achieved through the process od quarter-slicing or through the use of veneer cut in any fashion that produces a straight grain effect. Cut is radial to the pith to the extent that ray fleck is produced, and the amount of fleck is not limited.

Rails/Horizontal Edges- Top and bottom edge bands of door.

Random Matched (Mismatched)- A panel having a face made up of veneer strips of the same species which are selected and assembled without regard to color or grain, resulting in variations, contrasts and patterns of color and grain. Pleasing appearance is not required.

Ray Fleck- See Fleck, Ray.

Red/Brown- When referring to color and matching, veneers containing all heartwood, ranging in color from light to dark.

Repairs- A patch, shim, or filler material inserted and/or glued into veneer or a panel to achieve a sound surface.

Repairs, Blending- Wood or filler insertions similar in color to adjacent wood so as to blend well.

Rift Cut- A straight grain appearance achieved through the process of cutting at a slight angle to the radial on the half-round stay log or through the use of a veneer cut in any fashion that produces straight grain with minimal ray fleck.

Rotary Cut- Veneer produced by centering the entire log in a lathe and turning it against a broad cutting knife which is set into the log at an angle.

Rough Cut- Irregular shaped areas of generally uneven corrugation on the surface of veneer, differing from the surrounding smooth veneer and occurring as the veneer is cut by the lathe or slicer.

Running Match- The panel face is made from components running through the flitch consecutively. Any portion of a component left over from a face is used as the beginning component or leaf in starting the next panel.

Ruptured Grain- A break or breaks in the grain or between springwood and summerwood caused or aggravated by excessive pressure on the wood by seasoning, manufacturing, or natural processes. Ruptured grain appears as a single or series of distinct separations in the wood such as when springwood is crushed leaving the summerwood to separate in one or more growth increments.

Rustic- Lacking excessive refinement, having a rough surface or finish.

Sapwood- The living wood of lighter color occurring in the outer portion of a tree, sometimes referred to as sap.

Shake- A separation or rupture along the grain of wood in which the greater part occurs between the rings of annual growth. (See also RUPTURED GRAIN).

Sharp Contrast- For the purpose of this standard, this term means the veneer of lighter than average color should not be joined at the edges with veneer of darker than average color, and that two adjacent pieces of veneer should not be widely dissimilar in grain, figure and natural character markings.

Show Through (Sanding)- A defect caused by excessive sanding such that the crossbanding is visible through the face veneer.

Show Through (Telegraphing)- See Telegraphing

Skin- The face layer, whether flat or contoured, of flush doors, stile-and-rail doors, bending laminations, etc., typically composed of hardwood plywood (usually 3 ply), hardboard, or composition pane.

Sliced- Veneer produced by thrusting a log or sawed flitch into a slicing machine, which shears off veneer in sheets.

Slight- Visible on observation, but does not interfere with the overall aesthetic appearance with consideration of the applicable grade and common species characteristics of the panel.

Slip Matching- A process in which a leaf from a flitch is slid across the leaf beneath and, without turning, spliced at the joint. This process results in a panel or door which consists of all either loose or tight sides, minimizing barber pole or metamerism.

Sound Transmission Class (STC)- A single number rating system derived from measured values of sound transmission loss or the acoustical performance of a building element, such as a door, window or wall. The higher the STC value, the better the rating and the better the acoustical performance value. Tested in accordance with ASTM E413 and E90.

Split Heart- A method of achieving an inverted "V" or cathedral type of springwood (earlywood)/summerwood (latewood), plain- sliced (flat-cut) figure by joining two veneer components of similar color and grain. A cathedral type figure must be achieved by a single component in AA grade; the split heart method is allowed in grades A and B. Each half of a split heart shall be subject to the minimum component width requirements for grade A and B faces.

Splits- Separations of wood fiber running parallel to the grain.

Splits, Hairline- A thin, perceptible line, separation, crack, or absence of wood fiber in the surface of a material or at the joint of two pieces of wood or veneer

Staved Lumber Core (SLC)- A door core made with any combination of blocks or strips of wood glued together.

Stiles/Vertical Edges- The upright or vertical pieces of the core assembly of a wood flush door. Measurement. The width of the vertical edge/stile is measured at its widest side (the wide side of a beveled door).

Streaks, Mineral- Sharply contrasting elongated discoloration of the wood substance.

Structural Composite Lumber Core (SCLC)- An engineered wood product that is made by fusing a network of wood strands together with a water-resistant adhesive to produce a strong, solid and stable product that has true structural properties with excellent screw holding properties and very high split resistance.

Sweep- See Grain

Tape- Strips of gummed paper or cloth sometimes placed across the grain of large veneer sheets to facilitate handling and sometimes used to hold the edges of the veneer together at the joints prior to gluing.

Telegraphing- In veneer or laminated work, a defect caused by outlines and/or surface irregularities, such as frame parts, core laps, voids, extraneous core matter, etc., that are visible through the face veneers, applied top veneer, or laminate sheet following pressing and/or finishing. Also known as Show Through.

Thermally Fused Decorative Laminate Panel- A polyester or melamine resin-impregnated paper, thermally fused under pressure to a composite core.

Tight Side- In knife-cut veneer, that side of the sheet that was farthest from the knife as the sheet was being cut and containing no cutting checks (lathe checks).

Transom- An operable or non-operable fenestration product that is designed to be a companion product installed above a door system.

Twist- 1) A distortion in a wood piece caused by freed tension in the grain as the wood was drying. The surface appears to twist as the four corners of any face are no longer in the same plane. 2) In passage doors, any distortion in the door itself and not its relationship to the frame or jamb in which it is hung, measured by placing a straight edge or a taut string on the concave face

Veneer (wood)- A thin layer or sheet of wood rotary-cut, sliced, or sawed from a log or flitch. Thickness may vary from, but not exceed, 0.3mm [.012”] to 6.4mm [.252”] thick.

Vine Marks- Bands of irregular grain running across or diagonally to the grain, which are caused by the growth of climbing vines.

Voids- See Gaps.

Warp- 1) Any deviation from a true or plane surface, including bow, crook, cup, twist, or any combination thereof. Warp restrictions are based on the average form of warp as it occurs normally. 2) In passage architectural wood doors, any distortion in the plane of a door itself and not its relationship to the frame or jamb in which it is to be hung. (See also BOW, CROOK, CUP, TWIST)

White- When referring to color and matching, veneers containing all sapwood, ranging in color from pink to yellow.

Wood Filler- An aggregate of resin and strands, shreds, or flour of wood, which is used to fill openings in wood and provide a smooth, durable surface.

Wood Flush Door- An assembly consisting of a core and one or more edgebands, with at least two plies of overlay on each side of the core assembly. All parts are composed of wood, wood derivatives, fire-resistant composites, or decorative laminates.

Wormholes- Holes resulting from infestation of worms.

Worm Track (Scar)- A natural mark caused by various types of wood-attacking larvae. Worm tracks often appear as sound discolorations running with or across the grain in straight to wavy streaks. Sometimes referred to as “pith flecks” in certain species of maple, birch, and other hardwoods because of a resemblance to the color of the pith.

|